Core Technologies

Innovating today, shaping tomorrow.

Innovating today, shaping tomorrow.

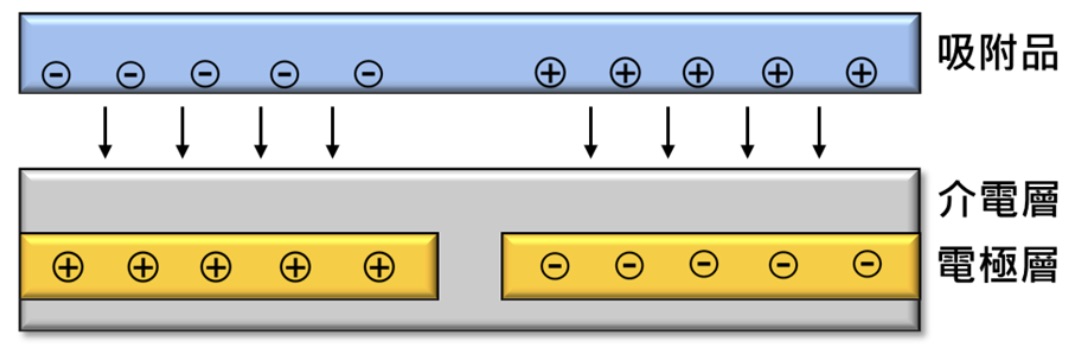

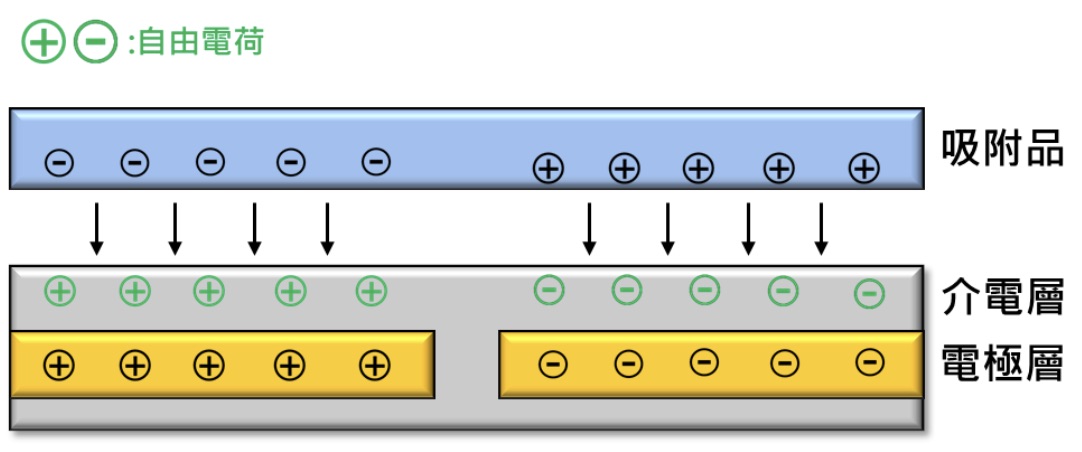

ESC are used to secure wafers during semiconductor manufacturing and to hold glass panels in the display industry.

Key advantages include:

Surface polish & Re-patterning

Ceramic plate de-bonding + L1

New ceramic plate + L2

New Heater + L3

Continuous Improvement Process

K-MAX specializes in the design and manufacturing of customized components, offering optimal solutions beyond standard specifications based on customer requirements. Our professional team is fully involved throughout the process—from design planning to machining, production, and related testing—to ensure higher precision and consistent quality. This comprehensive approach enhances equipment performance and meets the stringent demands of the semiconductor industry for precision components.

K-MAX has a highly skilled and experienced professional team that works closely with numerous international companies. We not only assist clients with Joint Design but also offer complete One-Stop Solutions.

We are committed to providing comprehensive product consultation services and conducting targeted R&D based on customer needs, delivering tailor-made customized products to meet the diverse demands of the market.

Sandblasting uses high-speed airflow to propel abrasive particles against a material’s surface. This process improves surface roughness and adhesion, removes oxidation layers, contaminants, or old coatings, and can also be used to create specific surface patterns. Additionally, sandblasting enhances surface texture to improve the adhesion of subsequent coatings or plating.

We are equipped with advanced automated sandblasting equipment and supported by an experienced technical team. This allows us to provide optimal solutions tailored to different materials and requirements, ensuring high-quality and efficient surface treatment.

Polishing is a technique that uses mechanical, chemical, or electrochemical methods to smooth the surface of materials, reducing roughness and enhancing gloss. This process not only improves the appearance of the material but also increases its corrosion resistance.

We are equipped with a wide range of professional polishing equipment and technologies. Our precision polishing services are tailored to different materials, ensuring high-quality surface gloss and flatness for each product.

Anodizing is an electrochemical oxidation process that forms a protective oxide layer on the surface of metal materials, enhancing corrosion resistance, wear resistance, hardness, and aesthetic appearance. This technique is especially suitable for aluminum and its alloys.

We utilize advanced anodizing technologies, offering both sulfuric acid and oxalic acid anodizing processes. We ensure uniformity and stability of the oxide layer and provide specialized insulation sealing techniques to meet a wide range of customer requirements.

Ceramic coating is a type of thermal spray technology in which ceramic materials (such as Al₂O₃ and Y₂O₃) are melted at high temperatures and sprayed onto the surface of a substrate at high velocity. The result is a coating with high hardness, excellent wear resistance, and strong heat resistance.

We are equipped with advanced ceramic coating equipment and technologies, offering high-quality coatings using materials such as Al₂O₃ and Y₂O₃ based on customer requirements. Our coatings significantly enhance product performance and service life.

We are committed to delivering comprehensive solutions through a wide range of surface treatment technologies—improving product quality and market competitiveness. For more information, feel free to contact our professional team!

Through these efforts, we not only deliver high-quality products and services but also consistently exceed customer expectations. Our goal is to build strong, long-term partnerships and become a trusted and reliable partner.

© Copyright – K-MAX Technology Co., Ltd. | design by Morcept